Can a Machine vision Inspection System Completely Replace Manual Visual Inspection?

With the machine vision industry becoming more and more familiar, more and more enterprises are considering replacing manual inspection with machine vision products. Can machine vision inspection system replace manual visual inspection in an all-round way? What is the scope of application? What are the limitations of machine vision inspection?

Machine vision requires a certain amount of capital investment

At present, the profit margin of small and medium-sized enterprises is limited. Automation upgrade needs funds and talent reserve. Because of various limitations, they are unwilling to invest a large amount of money, so machine vision detection will appear in large enterprises with strong strength. At present, labor costs are the largest, enterprises are also operating at high costs, and capital pressure is great, unless it is necessary to buy, otherwise they will live.

Limitations of Machine Vision Detection

1. In the application of visual inspection, it is often given some specific defect patterns, and machine vision is used to identify whether they have defects or not. But what we often encounter is that many obvious defects have been missed because they have not happened before, or because the patterns of occurrence are too diverse. If the replacement is manually detected, although he is not allowed to detect the defect in the operation process file, he will notice that there is a greater probability of detecting the defect and avoiding the occurrence of quality accidents.

2. In the application of machine vision defect detection, lighting is a difficult point. The algorithm is too difficult to do if the images you get need to be carefully considered before you can give the results. On the other hand, if we do a good job of polishing in the early stage and highlight the features to be detected, it is not difficult to implement the algorithm.

Prospect of Machine Vision Inspection

Machine vision testing will still be very marketable, because it solves a very serious problem in personnel testing: instability. Artificial visual inspection operators, no matter what reward and punishment system you design, will fail to check, because employees will be tired, there will be negligence. But machine vision detection equipment will not have such problems, as long as you write in the algorithm, every time will be seriously implemented, meticulous, tireless.

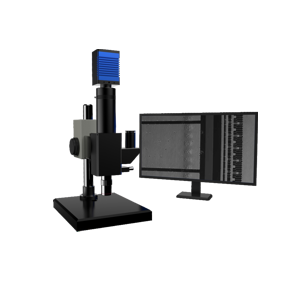

Machine Vision Inspection Instead of Manual Inspection.png

Comparisons of advantages and disadvantages between machine vision inspection and manual vision inspection

For the quality control department of the factory, we prefer to abandon manual inspection and choose machine vision which is silly but meticulous. Because for factories, the most important thing is to be "controlled", we can accept that there are some special and unacceptable defects that have been leaked, but we must know that some unacceptable defects that often occur can be found.

Machine Vision Inspection Cost

In terms of the cost of machine vision inspection, machine vision is cheaper than manual inspection in the medium and long term. General factories have QC posts, and the labor costs of the four QC posts are more than 200,000 yuan per year. And 200,000 is basically enough for a machine vision system, which is worth investing.

In summary, visual inspection system can not completely replace manual visual inspection in the short term. The main reason is that it is not intelligent enough and small and medium-sized enterprises are not willing to invest. But for the quality control of the factory, machine vision inspection is more reliable than manual inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com