In the battery manufacturing process, machine vision inspection is a very important technical means. As the battery manufacturing process involves numerous process links and requires a high degree of accuracy, machine vision inspection can improve production efficiency, ensure product quality, reduce labor costs and ensure production safety.

In the production process of blade batteries, the sealing nail is one of the key components to ensure the sealing performance of the battery. In order to ensure its accurate installation and stable position, it needs to be guided by the nail. Through the nail guidance, it can ensure that the sealing nail is inserted smoothly and accurately into the pre-drilled hole of the battery shell, avoiding problems such as installation position deviation or insufficient insertion depth. This improves the sealing performance of the battery and ensures the safe use of the battery.

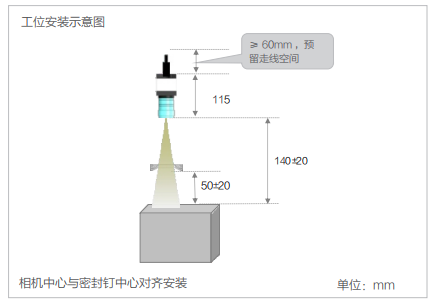

During the nail guiding process of sealing nails, efficient visual inspection and guiding can be achieved by using devices such as POMEAS Industrial lenses, cameras and light sources. The advantages of using these devices include the following:

1. High resolution: The Pumice lens is characterized by high resolution, which can clearly capture the detailed features of the sealing nails and provide high-quality input for subsequent image processing.

2. High-speed and high-precision: The camera in high-speed and high-precision mode can capture the trajectory and attitude information of the sealing nails, providing accurate guidance signals for robots or automation equipment.

3. Intelligent control: By using the combination of the Promise lens, camera and light source, intelligent image processing and control can be realized. For example, by adjusting parameters such as the angle and brightness of the light source, the characteristic information of the sealing nails can be emphasized, and the accuracy and stability of image processing can be improved.

4. Strong adaptability: these devices can be adapted to different application scenarios and needs, for example, customized configurations according to different specifications and types of sealing nails to improve the adaptability of detection and guidance.

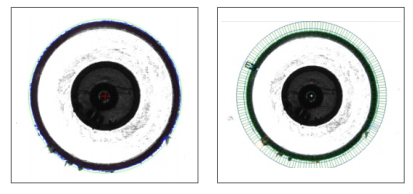

Detection effect diagram:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

Software Copyright :2021SR0176001 抄袭必究, 技术支持:誉新源科技

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION