In the electronics manufacturing industry, it is very important to accurately measure the terminal spacing, which not only affects the performance of electronic products, but also concerns its safety and stability. The measurement and control of terminal spacing can ensure the quality and productivity of electronic products. The traditional method of measuring terminal spacing is mainly through manual use of calipers, microscopes and other tools, this method is not only inefficient, but also prone to human error resulting in inaccurate measurement.

And the application of POMEAS fully automatic image measuring instrument (flash measuring instrument) can quickly and accurately complete the measurement of terminal spacing.

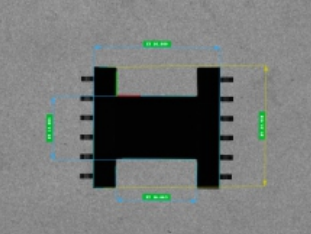

Detection effect diagram:

Advantages of the application of fully automatic image measuring instruments (flash measuring instruments) in the measurement of terminal spacing:

1. Fast measurement: The fully automatic image measuring instrument (flash measuring instrument) can quickly acquire and process image data, and the measurement of terminal spacing can be completed in a few seconds, which greatly improves the measurement efficiency.

2. Accurate data: the use of high-precision image processing algorithms, can accurately identify and measure the distance between the terminals, to avoid human error, to ensure the accuracy of the measurement.

3. Non-contact: The fully automatic image measuring instrument (flash measuring instrument) adopts non-contact measurement, which does not require direct contact with the terminals, thus avoiding possible damage to the terminals.

4. Multi-angle measurement: Terminal images can be obtained from multiple angles for comprehensive data analysis to ensure the accuracy of the measurement.

5. High degree of automation: fully automatic image measuring instrument (flash measuring instrument) can automatically complete the data analysis, results display and other operations, which greatly reduces the labour intensity of workers and improves production efficiency.

When it comes to terminal pitch measurement tasks, the use of the POMEAS IMAGE3 series of fully automated image measuring instruments (flash measuring instruments) not only simplifies the process and reduces labour costs, but also greatly improves the accuracy of the measurements and the efficiency of production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

Software Copyright :2021SR0176001 抄袭必究, 技术支持:誉新源科技

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION