Splice Measurement with the Advantages of Image Size Measuring Instruments

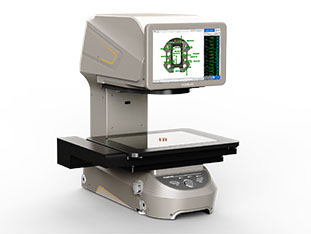

Image Dimension Measuring Instrument is a kind of fast dimension measuring equipment which consists of camera, light source, industrial lens, image processing system and so on. It does not require too much involvement of operators, and features non-contact, high stability, high precision and fast measurement, which effectively improves production efficiency and reduces labour costs.

Image Dimension Measuring Instruments are used for small precision parts dimensional inspection, in addition to a wide range of applications in the measurement of large-size parts splices. The following are the advantages of the Image Gauge:

1. High accuracy: image measuring instrument with high-resolution double telecentric optical lens, low distortion rate, with high-precision algorithm processing, measurement accuracy ± 2μm.

2. Fast measurement speed: any placement of the product, the instrument automatically identifies, a key measurement, the entire measurement process can be automated processing, more intelligent and convenient.

3. Simple operation, easy to get started: image measuring instrument without complex training, anyone can easily get started. Measurement data is generated on-site, evaluation results are generated automatically, statistical reports are generated with one click, and the format can be exported and saved as needed, which is of great help in the later data statistics and analysis.

POMEAS Image Dimension Gauge Splicing Application Example:

1.PCB board size measurement: Measurement of uncut PCB boards, multiple products at the same time, using the stitching mode, you can get all the images at once, and quickly complete the surface size inspection.

2. Automotive parts inspection: In automotive manufacturing, the need for body parts and other parts of the size of the inspection, for some of the larger workpieces, the use of the Promise image measuring instrument can greatly improve the measurement efficiency and accuracy of the measurement.

3. Flat glass size inspection: PAD glass manufacturing, its size requirements are very strict, you need to do a good job of quality control measurements, PMIS image measuring instrument can achieve its high precision, high speed and stable measurement.

The application of POMEAS image measuring instrument in large-size parts splicing measurement is very wide, with strong adaptability and feasibility, I believe that it will bring more and better development prospects to the production enterprises.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

Software Copyright :2021SR0176001 抄袭必究, 技术支持:誉新源科技

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION